3 axis vs 5 axis cnc|3 Axis vs 5 Axis Machining: Technical Differences & Industry : iloilo 3-Axis CNC Machining: Commonly used in industries like automotive, construction, and furniture manufacturing for producing simple parts and components. 5-Axis CNC Machining: Preferred in industries requiring high precision and complex geometries, such as aerospace, automotive, medical, and energy. Find local businesses, view maps and get driving directions in Google Maps.

3 axis vs 5 axis cnc,

Whether you're a seasoned professional or just starting, understanding the difference between 3-axis and 5-axis CNC machines is crucial. In this article, we'll delve into the intricacies of both types of machines and explore the advantages of 5-axis CNC machining.3-Axis CNC Machining: Commonly used in industries like automotive, construction, and furniture manufacturing for producing simple parts and components. 5-Axis CNC Machining: Preferred in industries requiring high precision and complex geometries, such as aerospace, automotive, medical, and energy.3 axis vs 5 axis cncLearn the key differences between 3-axis and 5-axis machining, their applications, benefits, and how to choose the right CNC technology to enhance your production efficiency and meet complex manufacturing demands.

When it comes to accurate high-speed machining, both 3-axis and 5-axis CNC machines have great capabilities but with notable distinctions between them. 5-axis CNC machines are the biggest, baddest, most complex machine tools available today.

3 Axis vs 5 Axis Machining: Technical Differences & Industry When it comes to accurate high-speed machining, both 3-axis and 5-axis CNC machines have great capabilities but with notable distinctions between them. 5-axis CNC machines are the biggest, baddest, most complex machine tools available today.3 axis vs 5 axis cnc 3 Axis vs 5 Axis Machining: Technical Differences & Industry When it comes to accurate high-speed machining, both 3-axis and 5-axis CNC machines have great capabilities but with notable distinctions between them. 5-axis CNC machines are the biggest, baddest, most complex machine tools available today.

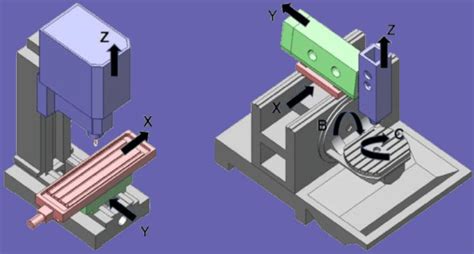

3-axis CNC machines move along three linear paths—X, Y, and Z—ideal for simpler cuts. In contrast, 5-axis CNC machines add two rotational movements, allowing the tool to approach the workpiece from various angles, facilitating the machining of complex geometries and intricate shapes. In this article, we’ll break down the key similarities and differences between two popular types of CNC machining (3-axis vs. 5-axis) — and explain when it might make sense to use one over the other.

In this post, we will provide an in-depth analysis of 3 axis vs 5 axis CNC to help you make an informed decision. Part 1. What is 3 Axis CNC? Part 2. What is 5 Axis CNC? Part 3. Key Differences Between 5 Axis vs 3 Axis CNC. Part 4. How to Choose the Right CNC Machining? Part 5. Still Unsure Which CNC Machining Method to Choose? In this article, we will explain the key differences between 3-axis and 5-axis CNC machines and help you identify which type is best for your specific manufacturing needs. A 3-axis CNC machine operates in three directions (X, Y, and Z), making it suitable for simpler, flat, and less complex cuts.

3 axis vs 5 axis cnc|3 Axis vs 5 Axis Machining: Technical Differences & Industry

PH0 · 3 Axis vs 5 Axis Machining: Technical Differences & Industry

PH1 · 3 Axis vs 5 Axis CNC: Which is Better

PH2 · 3